With in-house quality testing and certification, you can count on quality materials delivered with proper documentation.

Empower

Empower Enhance

Enhance Excel

Excel

Incoloy 800 U Tube Manufacturer

U TUBES: ASTM B163 Incoloy 800 U Tube | ASME SB163 Incoloy 800 U Tube | DIN 1.4876 U Tube | UNS N08800 U Tube | JIS NCF 800 U Tube | BS NA 15 U Tube | EN X10NiCrAlTi32-20 U Tubing | GOST ЭИ670 U Tube

ASTM B163 Incoloy 800 U Tubes, Incoloy BS NA 15 U Tubing, Incoloy DIN 1.4876 U Tubes, Incoloy Alloy 800 U Tubo, ASME SB163 Incoloy 800 U Tubing Manufacturer in India, Incoloy 800 U Tubes Supplier in Qatar, Alloy 800 U Tubing Exporter in Australia.

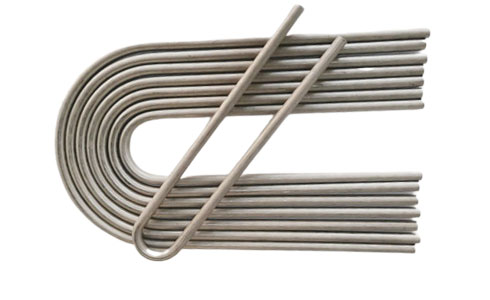

Incoloy 800 U tubes are specialized heat exchanger tubes made from Incoloy 800, a nickel-iron-chromium alloy known for its excellent resistance to high-temperature corrosion and oxidation. These U-shaped tubes are designed for heat exchange applications in demanding industrial environments.

Incoloy 800, also known as Alloy 800, belongs to a group of alloys developed for high-temperature applications. It is primarily composed of nickel (around 32-37%), iron (around 39-43%), and chromium (around 19-23%), with small additions of other elements such as aluminum and titanium. This alloy’s unique combination of elements gives it exceptional resistance to oxidation, carburization, and sulfidation, making it suitable for applications involving elevated temperatures.

The ASTM B163 specification outlines the requirements for seamless nickel and nickel alloy condenser and heat-exchanger tubes. Incoloy 800 U tubes are typically used in industries like chemical processing, petrochemical, and power generation, where they are required to efficiently transfer heat between different mediums while withstanding high-temperature and corrosive environments.

These U-shaped tubes offer a compact and efficient design for heat exchange systems. They can be customized in terms of outer diameter (ranging from 12.70 mm to 50.80 mm), wall thickness (from 0.71 mm to 5.0 mm), and length (up to 24 meters). This flexibility in design allows engineers to tailor the U tubes to meet specific project requirements, ensuring optimal thermal performance and system reliability.

In addition to ASTM B163, Incoloy 800 U tubes can conform to other international standards such as ASME, DIN EN (German), NF (AFNOR), and JIS (Japan). This international compliance underscores their versatility and suitability for use in various global industries and heat exchanger applications.

Incoloy 800 Seamless U Tube, Alloy 800 U Tubes Exporter in Dubai, Incoloy 800 U Tubing, Incoloy GOST ЭИ670 U Tubing, Alloy 800 U Tubes, Incoloy N08800 U Tube, ASTM B163 Incoloy 800 U Tubes, Incoloy EN NiCr15Fe U Tubing, Incoloy AFNOR NC15FE11M U Tubes Stockiest, Supplier.

Incoloy 800 U Tube Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Incoloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

Alloy UNS N06800 U Tubes Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Incoloy 800 | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

ASTM B163 Incoloy 800 U Tubing Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

|---|---|---|---|---|---|---|---|---|

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

Incoloy 800 U Tubes Standard Specifications

Spec. No.

Title

Scope

ASTM B163

ASTM B163 Standard Specification for Seamless Tubes Nickel and Nickel Alloy

This specification covers seamless tubes of nickel and nickel alloys, for use in condenser and heat-exchanger service.

Let’s discuss about your ongoing project

Size Range

- Outer Diameter: 12.70 mm to 50.80 mm

- Wall Thickness: 0.71 mm – 5.0 mm

- Length: Up to 24 mtr long

- Specifications: ASTM, ASME, DIN EN (GERMAN), NF (AFNOR), JIS (JAPAN)

Supply Condition

- Bright Annealed / Solution Annealed & Passivated

Features

- Ability to supply tubes with stringent NDT Testing, Special Chemistry, Lower Residual Stress values.

- OD Polishing : Grit Polish from 120 to 600.

- Closer Dimensional Tolerance & higher Corrosion Resistance etc.

Incoloy 800 U Tube Quality Control

To ensure a quality product, MPJ is holding certificate ISO 9001:2015, ISO 45001, OHSAS 18001, & CE-PED. We are also members of various renowned agencies and Chambers of Commerce including MASSMA, EEPC, FICCI, FIEO, Indian Merchants Chamber, etc. With state-of-the-art manufacturing processes, contemporary technologies, and proficient services, we consider: offering the finest quality, best in class products. Compliance with specifications as per standards, Outer Diameter, Thickness, Inside Diameter, Inside Finish, Marking, Ends, and Finishing. This ensures that we never face a rejection of the Incoloy 800 U Tube supplied.

Brand –

800 Incoloy U Tubing are marked in requirement of the international standards.

Format: ” BRAND-SIZE-SPECIFICATION-GRADE-HEAT NUMBER-LOT NUMBER “

This marking helps for the identification of the Alloy 800 U Tube and supported with the Material Test Report. It is 100% traceable to our mill.

Incoloy 800 U Tubes Packing & Documentation

ASTM B163 Incoloy 800 U Tubes are surface wash and clean to remove all impurities and stock in the warehouse. Then it is wrapped in thin plastic and also it ends are protected by plastic caps to avoid any damage in transit. 800 Incoloy U Tube is bundled in bubble wrap followed by assorting them in colored plastic bundles. An outer rope is tied to protect the tubing and they are packed in wooden box or container.

MPJ Provide Alloy 800 U Tube and Incoloy UNS N08800 U Tubes with all necessary documents such as commercial invoice, packing list, Test Reports, HS Code, Country of Origin attested by the chamber of commerce, Fumigation Certificate, Warranty Letter, and Base Material Certificates. Every lot is supplied with a material test certificate as per EN 10204 NACE 3.1 standards indicating the chemical and mechanical properties of the Inconel 800 U Tubing.

We also confirm the guarantee of the Incoloy 800 U Tubes supplied as per Purchase order specifications and attest the same in the Material Test Certificate. We also welcome any third party inspection from an agency nominated by the customer to comply with NACE 3.2 Certification if required by the customer at an extra cost.

Incoloy 800 U Tube Application Industries

- Oil & Gas Exploration

- Petrochemicals and Refineries

- Cross Country Pipe Line for Gas & Water

- Pipes for Engineering purpose

- Thermal, Nuclear and Solar Power Plants

- Desalination Plants

- Chemical Industries

- Aerospace

- Atomic Energy

- Pharmaceutical

- Food and Dairy

- Automobile

People Also Search For

ASTM B163 Incoloy 800 U Tubes Supplier in Australia | ASME SB163 Alloy 800 U Tubes Exporter in Qatar | 800 Incoloy U Tube | Incoloy 800 U Tube Stockiest in India | Incoloy Alloy 800 U Tube | 800 Incoloy U Tube Specification | Incoloy 800 U Tube Stockiest in India | Incoloy 800 U Tube | ASTM B163 Incoloy 800 Seamless Tubes | Incoloy 800 U Tubo | Incoloy 800 U Tube Sizes in Stock | Incoloy 800 U Tube Forms in Stock | 800 Incoloy U Tube.

Incoloy 800 U Tube Inspection & Material Specification | ASME SB163 Incoloy 800 U Tube Size | ASTM B163 Alloy 800 U Tube Installation | Incoloy 800 U Tubes Exporter in Qatar | Incoloy 800 U Tube Installation Guidelines | Incoloy 800 U Tube OD | 800 Incoloy 24″ NB U Tube Supplier in South Africa | 800 Alloy 0.5 mm U Tube | Incoloy Alloy 800 U Tubing | Incoloy 800 Welded U Tube | Incoloy 800 U Tubes Price in India | Incoloy 800 U Tube Dimensions, Diameter, Thickness and Drawing | Incoloy 800 U Tube Stockiest in India.

Industrial Pipes & Tubes Supply and Export Network Countries List

| Albania | Andorra | Armenia | Austria |

| Azerbaijan | Belarus | Belgium | Bosnia and Herzegovina |

| Bulgaria | Croatia | Cyprus | Czech Republic |

| Denmark | Estonia | Finland | France |

| Georgia | Germany | Greece | Hungary |

| Iceland | Ireland | Italy | Kazakhstan |

| Kosovo | Latvia | Liechtenstein | Lithuania |

| Luxembourg | Macedonia | Malta | Moldova |

| Monaco | Montenegro | Netherlands | Norway |

| Poland | Portugal | Romania | Russia |

| San Marino | Serbia | Slovakia | Slovenia |

| Spain | Sweden | Turkey | Ukraine |

| United Kingdom | Vatican City |

| Algeria | Angola | Benin | Botswana |

| Burkina Faso | Burundi | Cabo Verde | Cameroon |

| Central African Republic (CAR) | Chad | Comoros | The Democratic Republic of the Congo |

| Republic of the Congo | Cote d’Ivoire | Djibouti | Egypt |

| Equatorial Guinea | Eritrea | Ethiopia | Gabon |

| Gambia | Ghana | Guinea | Guinea-Bissau |

| Kenya | Lesotho | Liberia | Libya |

| Madagascar | Malawi | Mali | Mauritania |

| Mauritius | Morocco | Mozambique | Namibia |

| Niger | Nigeria | Rwanda | Sao Tome and Principe |

| Senegal | Seychelles | Sierra Leone | Somalia |

| South Africa | South Sudan | Sudan | Swaziland |

| Tanzania | Togo | Tunisia | Uganda |

| Zambia | Zimbabwe |

| Antigua and Barbuda | Bahamas | Barbados | Belize |

| Canada | Costa Rica | Cuba | Dominica |

| Dominican Republic | El Salvador | Grenada | Guatemala |

| Haiti | Honduras | Jamaica | Mexico |

| Nicaragua | Panama | Saint Kitts and Nevis | Saint Lucia |

| Saint Vincent and the Grenadines | Trinidad and Tobago | United States of America | Argentina |

| Bolivia | Brazil | Chile | Colombia |

| Ecuador | Guyana | Paraguay | Peru |

| Suriname | Uruguay | Venezuela |

| Afghanistan | Armenia | Azerbaijan | Bahrain |

| Bangladesh | Bhutan | Brunei | Cambodia |

| China | Cyprus | Georgia | India |

| Indonesia | Iran | Iraq | Israel |

| Japan | Jordan | Laos | Lebanon |

| Malaysia | Maldives | Mongolia | Myanmar (Burma) |

| Nepal | North Korea | Oman | Pakistan |

| Palestine | Philippines | Qatar | Russia |

| Saudi Arabia | Singapore | South Korea | Sri Lanka |

| Syria | Taiwan | Tajikistan | Thailand |

| Timor-Leste | Turkey | Turkmenistan | United Arab Emirates (UAE) |

| Uzbekistan | Vietnam | Yemen | |

| Australia | Fiji | Kiribati | Marshall Islands |

| Micronesia | Nauru | New Zealand | Palau |

| Papua New Guinea | Samoa | Solomon Islands | Tonga |

| Tuvalu | Vanuatu |