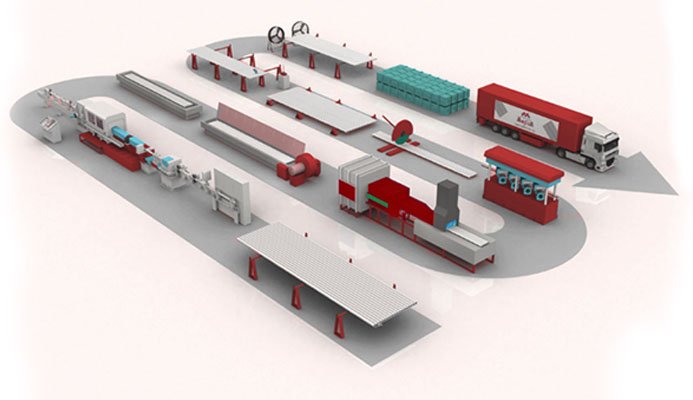

STAINLESS STEEL SEAMLESS TUBES (BRIGHT ANNEALED)

- Raw Material Inspection

- Pilgering

- Degreasing

- Hot Drying

- Heat Treatment

- Straightening

- Cutting & Deburring

- Inside Cleaning

- VDI & Testing

- Tube Drying

- Packing

- Dispatch

STAINLESS STEEL SEAMLESS TUBES (ANNEALED & PICKLED)

- Raw Material Inspection

- Pilgering

- Degreasing

- Heat Treatment

- Straightening

- Cutting & Deburring

- Passivation

- VDI & Testing

- Tube Drying

- Packing

- Dispatch

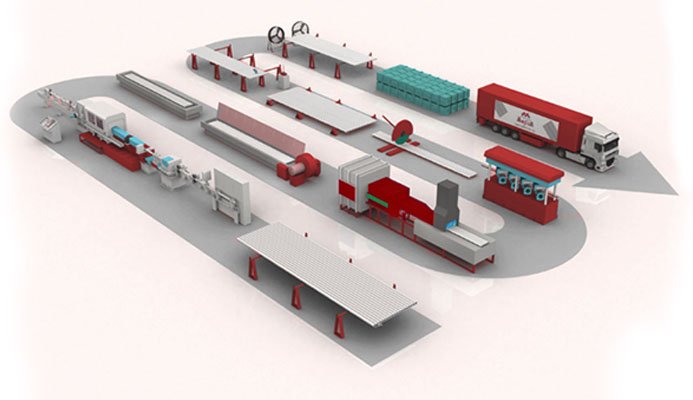

STAINLESS STEEL SEAMLESS U TUBES (ANNEALED & PICKLED)

- Raw Material Inspection

- Pilgering

- Degreasing

- Heat Treatment

- Straightening

- Cutting & Deburring

- Passivation

- VDI & Testing

- U Bending

- U Bend Heat Treatment

- Final Inspection

- Tube Drying

- Packing

- Dispatch

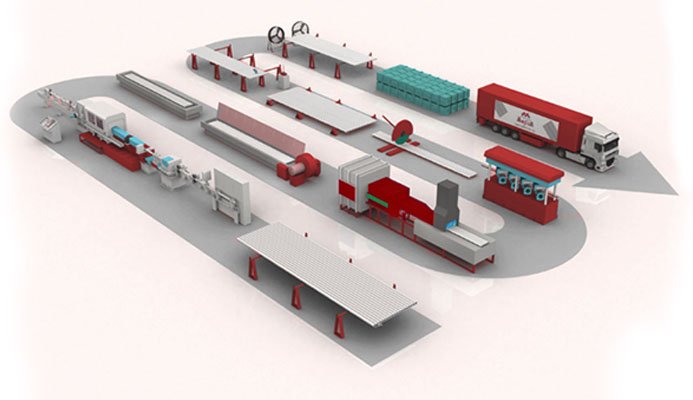

STAINLESS STEEL SEAMLESS PIPES (ANNEALED & PICKLED)

- Raw Material Inspection

- Pickling

- Coating

- Drawing

- Decoating

- Heat Treatment

- Straightening

- Cutting & Deburring

- Passivation

- VDI & Testing

- Tube Drying

- Packing

- Dispatch

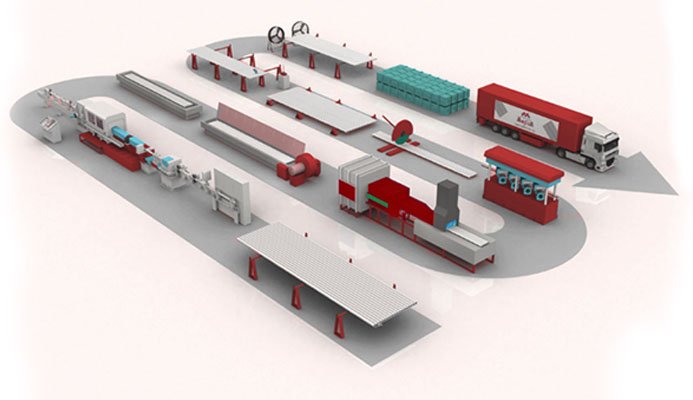

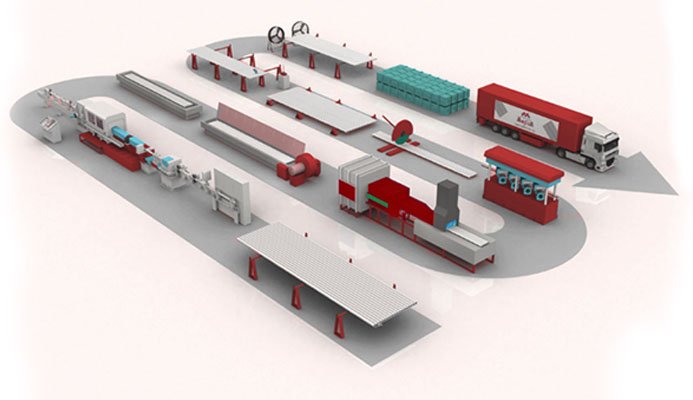

STAINLESS STEEL WELDED PIPES & TUBES

- Raw Material Inspection

- Forming, Welding & Sizing

- Heat Treatment

- Straightening

- Cutting & Deburring

- Pickling & Passivation

- VDI & Testing

- Tube Drying

- Packing

- Dispatch